Image above: Towill surveyor James LaBasco makes the tight descent into the pipe. They used special safety equipment and procedures throughout the project.

Sponsored by Trimble

A California firm uses Trimble solutions to manage a tight schedule and difficult conditions.

Total stations and scanning provide precise data for rehabilitating an aging water line.

As buried water pipes age, utility companies face costly repairs or replacement of critical infrastructure. Techniques such as sliplining can greatly reduce costs that come with these projects. To plan a successful sliplining project, designers need accurate information on the existing pipes.

Deep Challenges

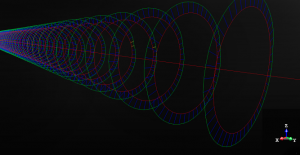

Clash detection analysis shows the best fit centerline, existing pipe walls and proposed sliplining. Yellow line segments indicate potential clearance issues.

When a California utility needed to rehabilitate a 90-year old buried water pipeline, it faced daunting challenges. Inspections of the 54-inch (137 cm) diameter steel pipe revealed the need for extensive work. Because the pipeline lies close to major traffic arteries and a water treatment plant, excavation to repair or replace it would be prohibitively expensive and disruptive. Engineers decided to use sliplining to install a new pipe inside the existing water main. The approach would bypass major excavation and greatly reduce the time and cost of upgrading the old infrastructure.

California-based Towill, Inc. was called to provide precise information on the interior of roughly 1,800 ft (550m) of the active, pressurized waterline. In addition to determining the horizontal and vertical alignment of the pipe, they needed to provide data on the pipe’s ovality, or deformation from its original circular shape caused by external loading at the surface. Engineers decided to use sliplining to install a new pipe inside the existing water main. (In sliplining a new carrier pipe is inserted inside an existing pipe to repair leaks and provide structural integrity.)

The only way to gather such dense, detailed data was to go inside the buried pipe. Because the pipe served as an active water main, Towill had just eight days to complete the survey.

Towill surveyor Jared McNeil operates the Trimble SX10 during the pipe survey. The instrument provided scanning along with precise survey measurements.

Getting Down to Work

Towill surveyor Tony Gaytan works next to spherical and checkerboard targets. The team spent eight days collecting traverse and scanning data.

To handle the work, the Towill team decided to combine 3D scanning with total station measurements from their Trimble S7 total station. The project presented an opportunity to test the Trimble SX10 scanning total station; both instruments were controlled using Trimble Access software running on a Trimble Tablet. Towill also owned a Faro Focus X330, which could handle the short-range measurements needed for the work.

“It was difficult work from the very beginning,” said Towill geospatial specialist JR Gregory. As the project began, the Towill crew used the Trimble S7 to conduct an open traverse through the pipe, measuring multiple angle sets at each setup. They followed with the SX10, which provided an independent check on the traverse and also produced scanning data on control targets. Both instruments performed well in the dank, low-light conditions.

Accessing the pipe from three different locations, the teams completed the traverse and scanning in eight days. Using traverse control stations roughly 150 to 200 ft (45 to 60 m) apart, the team completed a total of 130 scanning setups at intervals of 15 feet (5 m). When the surveyors were done, the pipe was sealed and water flow resumed. There would be no going back.

Results Flow Quickly

Gregory used Trimble Business Center software (TBC) to process data from the S7 and SX10 into coordinates on the control points. Then he processed the SX10 scans and converted them into a project in Trimble RealWorks software (TRW). “The results were well within our project tolerances,” Gregory said. “The redundant traverse provided an additional QA/QC benefit of the work.”

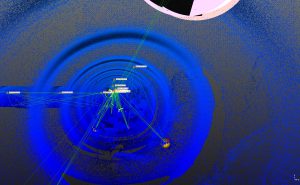

Point cloud with control network nearing a bend in the pipe. The ghost images of the surveyors were removed during processing.

Gregory used TRW to register the scanner data into a single point cloud. He created a best-fit horizontal and vertical alignment along the center of the pipe. The data revealed multiple horizontal and vertical deflections not shown on earlier plans or as-built drawings.

To model the proposed slipline, Towill technicians used TRW to create a design cylinder and automatically compare it to the point cloud. This analysis enabled Towill to recommend the optimal size for the slipline and also to identify areas of potential problems. In addition to technical reports, Towill exported the results in AutoCAD Civil3D and LAS formats, enabling the team to visualize and share data with the client’s engineers.

The survey more than paid for itself. Using the Towill results, the client could install the largest possible liner to maximize the pipe capacity without major excavation. They avoided millions of dollars of costs for excavation, traffic delays and economic distress to local businesses.

“The survey and analysis enabled engineers to adjust for problems before they occurred. Our work greatly reduced changes in the field that the client might have encountered if forced to use less accurate and comprehensive data.” — John T. May, PLS Project Manager

Learn more on the Trimble SX10: https://geospatial.trimble.com/products-and-solutions/trimble-sx10