What the Lunabotics 2024 competition tells us about lidar and the future of engineers

If I were to use the word “regolith” would you know what I meant? Honestly, I didn’t until I sat down with Shawn Asher and talked about a robotics competition he took part in. In the famous words of the security guard from Joe Dirt, “Don’t try to church it up son, don’t you mean dirt?”

Regolith is another word for dirt. On Earth, we have soil mixed with organic living matter, but on other planets and the moon, it is a consistency more like dust. Generally, when people refer to regolith, they are using a fancy word for moon dirt.

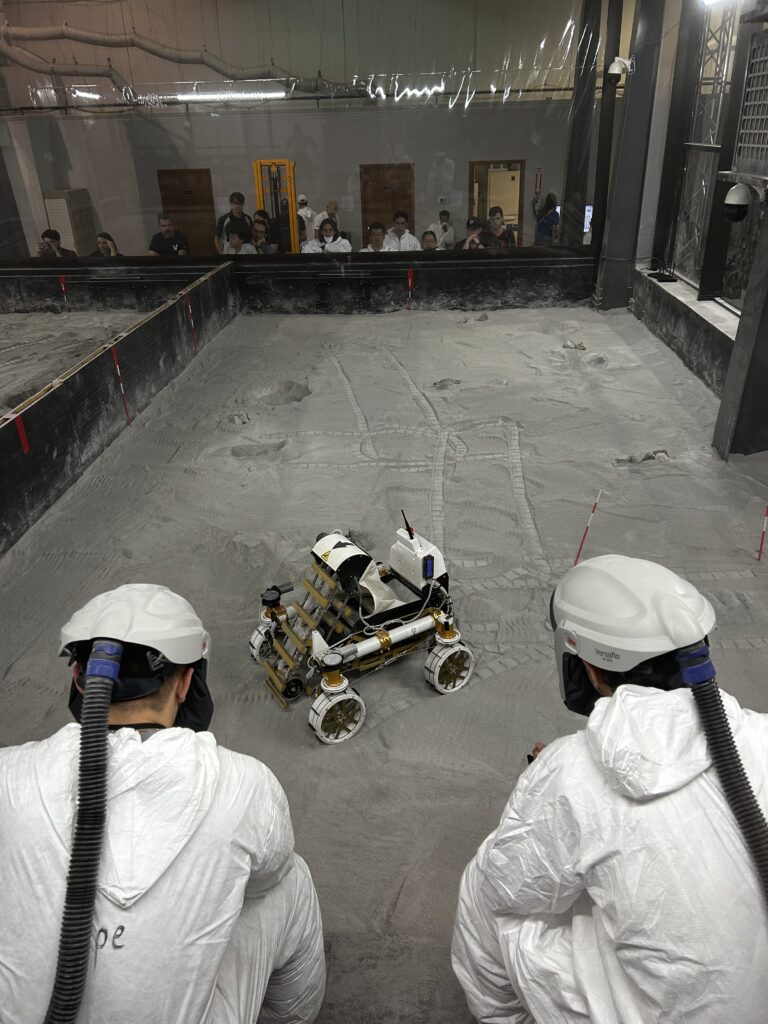

Two judges monitor the competition.

Asher’s journey began with a call from Parks Easter, who was deeply involved in developing moon-like regolith for research and educational purposes. Parks needed an expert in lidar technology to ensure that the robots used in the competition could accurately measure the volume of collected regolith. Asher, with his extensive background in lidar technology, was the perfect fit for this challenge.

One of the first tasks was to select a suitable lidar sensor that could perform reliably in a dusty, harsh environment. Asher’s extensive research led him to the RIEGL VZ-600i, a state-of-the-art lidar sensor known for its robustness and precision. Tan Nguyen, the RIEGL USA division manager of terrestrial laser scanning, assured Asher that the VZ-600i was not only capable of being integrated into a robot but also equipped with onboard processing capabilities to handle volume calculations. This was crucial because the environment in which the robots operated was designed to simulate the moon’s surface as closely as possible, complete with fine, pervasive dust particles.

The reliability and accuracy of the lidar sensor were paramount. The competition’s environment, a large room divided into two sections, required precise measurement tools. To ensure consistency, two RIEGL VZ-600i sensors were used. RIEGL provided one, and Allen & Company provided the other. The challenge was to mount these sensors in a location free from vibrations and other disturbances that could introduce errors in the measurements. Given the stringent conditions—entry to the area required full protective gear—Asher and his team had to devise a solution that minimized the need for adjustments or repairs during the competition.

With the technical setup finalized, the competition commenced. More than 50 collegiate teams from across the United States gathered at the University of Florida for the first round. The primary task for each robot was to navigate the simulated lunar environment, collect regolith, and create a pile for volume measurement. After each robot completed its task, the regolith had to be raked and rescanned to establish a new baseline surface for subsequent measurements. This process ensured that each robot had an equal opportunity to demonstrate its capabilities.

During competition, an autonomous vehicle builds a berm with near real-time updates via lidar data from RIEGL VZ-600i.

The robots then collected regolith, which was scanned to create a surface model. The lidar system then performed a volume calculation. This process was crucial in determining the efficiency and effectiveness of each robot. Out of the 50 teams, 10 were selected to move on to the next round at Kennedy Space Center, where the regolith presented a new challenge due to its magnetic properties.

While the laser scanning was a small part of the overall competition, its impact was significant. Many of the participating teams had only encountered lidar technology in the context of self-driving cars or basic distance measurements. This competition exposed them to the broader potential of lidar, including environmental mapping and route planning. This exposure is invaluable for young engineers, helping them understand the practical applications of their studies in real-world scenarios.

The competition at Kennedy Space Center introduced a new layer of complexity. The regolith used there had magnetic properties, presenting additional challenges for the robots and the lidar sensors. However, the RIEGL VZ-600i sensors proved up to the task, demonstrating their versatility and reliability in diverse conditions.

The teams that advanced to this stage had to adapt to the new environment, recalibrating their robots and adjusting their strategies to handle the magnetic regolith. This stage of the competition further underscored the importance of adaptability and innovation in engineering, as teams had to think on their feet and troubleshoot unexpected issues.

Throughout the competition, the role of lidar technology remained pivotal. The ability to accurately measure the volume of collected regolith was essential for determining the success of each robot’s task. The precision and reliability of the RIEGL VZ-600i sensors ensured that the measurements were consistent and accurate, providing a fair basis for judging the competition.

Asher’s involvement in the competition didn’t end with the selection and setup of the lidar sensors. He played an ongoing role in ensuring that the sensors operated flawlessly throughout the event. This involved monitoring the data collected, troubleshooting any issues that arose, and supporting the teams as they navigated the competition’s challenges. Nguyen also assisted Asher with the volume calculations during the testing phase, ensuring the data accuracy.

Suited up in the controlled “moon like” environment.

In the end, Lunabotics 2024 was more than just a contest. It was a valuable learning experience. The students gained hands-on experience with advanced technologies and learned to apply theoretical knowledge in practical situations. They also developed problem-solving skills, teamwork, and the ability to adapt to new challenges—skills that are essential for any engineer.

For Asher, the competition was an opportunity to mentor the next generation of engineers and share his expertise in lidar technology. It also provided a platform to demonstrate the capabilities of the RIEGL VZ-600i sensors in a challenging and innovative application.

Lunabotics 2024 highlighted the importance of interdisciplinary collaboration in advancing technology. The partnership between Exolith Labs, the University of Florida, RIEGL, and the participating teams showcased how combining expertise from different fields can lead to innovative solutions and new discoveries.

As the competition ended, it was clear that everyone involved had gained valuable insights and experiences. The students walked away with a deeper understanding of lidar technology and its applications and a sense of accomplishment from overcoming the challenges presented by the competition. Asher and his colleagues saw firsthand the potential of the next generation of engineers and were inspired by their creativity and determination.

Looking ahead, the success of Lunabotics 2024 opens the door for future events and collaborations. It sets a precedent for using robotics competitions as a platform for education and innovation, inspiring more students to pursue careers in engineering and technology. The lessons learned from this competition will undoubtedly inform future efforts to develop and refine technologies for space exploration and other challenging environments.

Lunabotics 2024 was a groundbreaking event that brought together talented individuals from various fields to tackle a unique and challenging problem. Through their collaboration and innovation, they demonstrated the power of technology to solve complex issues and inspire the next generation of engineers. The competition not only advanced our understanding of lidar technology and its applications but also highlighted the importance of hands-on, practical experiences in engineering education.

Mack Kowalski has more than 10 years of experience in layout management and laser scanning to provide innovative solutions and services to our clients and partners. His passion to push the boundaries of technology and delivering high-quality results in every project led him to co-found LiDAholics consulting firm.