Surveyors and geospatial professionals will play a key role in rebuilding Baltimore’s Francis Scott Key Bridge

It has been said many times that land surveyors are the first to arrive at any construction site and the last to leave. This old adage is ever truer in the case of bridge construction where precision and alignment can be the difference between success and failure. This accuracy can only be obtained by using precise instruments and a rigid methodology. Land surveyors and geodesists excel at this.

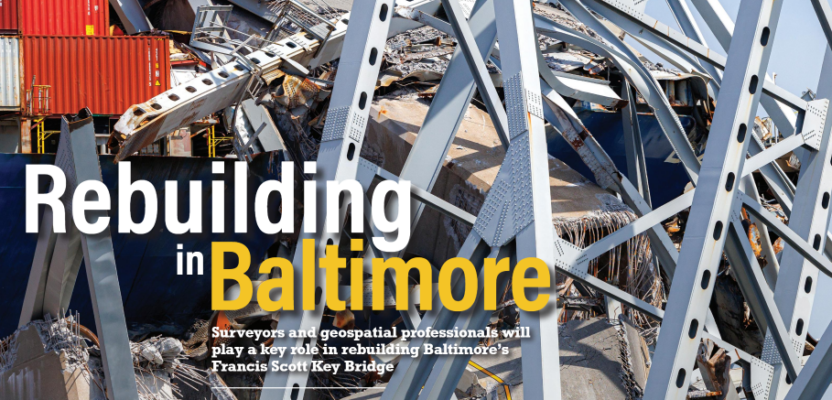

The superstructure of the collapsed Francis Scott Key Bridge rests on the container ship Dali.

In the recent disaster involving a container ship hitting and demolishing the Francis Scott Key Bridge in Baltimore, Maryland, we can easily predict that our profession will play a key role in the analysis of what is left of the structure and the eventual replacement of the bridge.

Construction on the Francis Scott Key Bridge began in 1972 and it opened on March 23, 1977. Its construction completed Interstate 695, which is the beltway around Baltimore. The Key Bridge carried 12.5 million vehicles in 2023, averaging more than 34,000 vehicles a day. It spanned the Patapsco River, the only shipping channel in and out of the Port of Baltimore, which is among the top 20 ports in the United States by tonnage and number of containers handled. Baltimore is 10th largest port for dry bulk and the largest import/export port in the U.S. for cars and light trucks.

We reached out to some land surveying companies in the Baltimore area and all of them agreed that it was too early to engage land surveyors in the process and none of them have been contacted yet. They are all in agreement that the new bridge will be a considerable upgrade to the old one. They expect the new structure to be wider, to accommodate more vehicular traffic between riverbanks and to be taller to increase the tonnage available to the port.

Some of these professionals in the Baltimore area also believe that by upgrading the bridge, the port will be more competitive to nearby ports and that would force the authorities to, simultaneously, upgrade the port itself, creating more work for land surveyors.

So, we can safely assume that the bridge will be replaced urgently, so let us analyze the different areas of geospatial sciences that will be involved in the process.

So, we can safely assume that the bridge will be replaced urgently, so let us analyze the different areas of geospatial sciences that will be involved in the process.

Bathymetry: The most urgent issue was to re-open the channel to allow the Port of Baltimore to resume shipping activities. In order to do this, demolition companies had to locate and remove metal and concrete debris from the bottom of the channel. Once these operations have taken away the larger pieces, a detailed bathymetry survey was conducted before the first of the five ships stuck in the harbor after the collapse was allowed to leave on April 29.

3D Modeling: Once all the debris has been removed and the operation of the port is normalized, it would be time to replace the bridge. The big question at this point would be whether to replace the Francis Scott Key bridge with a similar structure or take the opportunity to upgrade to a wider model to accommodate for the increased traffic. Given that ships are wider, higher and heavier than in the 1970s, when the bridge was built, it is reasonable to assume that a wider and taller bridge will replace it. In any case, most of the existing non-metal supporting structure will be analyzed for demolition and debris removal. Precision laser scanners will be used to create high-accuracy 3D models of each pilar to compare and evaluate soundness and plan demolition strategy.

The majestic superstructure of the Francis Scott Key Bridge spanning the Patapsco River near Baltimore before it was struck by a cargo ship and collapsed.

Precision Mapping: Once all the debris has been removed it will be necessary to conduct a high-accuracy mapping effort of both sides of the river to analyze the potential sites for the abutments of the new structure. This highly accurate map will complement the bathymetry of the river floor in order to provide design architects and engineers with the necessary topographic information to design a new bridge.

Staking on Land: Once the design is ready it would be the time for land surveyors and geodesists to accurately locate the design anchor points both on the riverbanks and underwater. This will require the use of microgeodesy, in some cases, due to the strict requirements of prefabricated metal structures that need to fall in place within 1/16 of an inch into fittings that have been installed into concrete foundations. This is one of the most crucial and precise events in any construction involving large metal assemblies.

Staking on Water: It is safe to assume that the new bridge will have at least two foundations under water given the distance between riverbanks. Already the Francis Scott Key Bridge had a main span of 1,200 feet (366 meters) and was the third-longest of any continuous truss in the world. That means that engineers will try to replicate or, given the advancement of new materials and construction technologies, even stretch a little bit of the distance to accommodate more fluvial traffic. This will mean locating and marking these underwater structures with great accuracy and that would require surveying techniques.

U.S. Coast Guard and other officials approach the collapsed Francis Scott Key Bridge in Baltimore.

Construction Site Follow-up: With the introduction of inexpensive drones and highly accurate processing software, the sub-industry of construction monitoring has exploded into a must-have for any large building site and this reconstruction endeavor will be one of the largest building sites in the world for years. Drones will fly the entire span of the design at least once a week and the results will be downloaded into building information modeling (BIM) software that would create statistics that, in turn, would help architects and engineers plan a better construction strategy.

Creation of As-Built 3D Digital Twin: Once the bridge has been finished, there will be a final flight of the mapping drone and a deep laser scan of every nook and cranny of the structure, both on the ground (girders, abutments, etc.) to create a digital twin of the bridge.

Monitoring of Superstructure: During the final stages of construction, high precision GNSS antennas will be placed in strategic locations throughout the superstructure to create a deformation model that would allow maintenance engineers to follow, using the digital twin, the different areas of the bridge that are subject to twists and bends due to environmental and load conditions.

Structure Inspections: After construction is completed a strict schedule of inspections will be planned and executed periodically to make sure the various components are not deteriorating outside of the design parameters. Issues like rust and fissures are important in determining the longevity of any structure constantly exposed to water. Drones will be extensively used for this purpose and all the information will be loaded into the BIM for follow-up.

As we can see by this basic enumeration of positioning tasks, land surveyors, geodesists, and photogrammetrists will be deeply involved in the two or three years of construction and then over the life span of the bridge as constant monitoring of deformation parameters require adjustments to keep the structure safe.

The next few years will be an exciting time for the surveying community in the Baltimore area, given the enormous amount of work that this project and the potential upgrade of the port itself will bring to the area.