Laser scanning helped the city create an aquarium great for wildlife and visitors

Seattle, Washington, renowned for its vibrant cultural scene and breathtaking natural landscapes, is set to welcome a groundbreaking addition to its skyline: the Seattle Aquarium. Spearheaded by Turner Construction, recognized for its expertise in large-scale projects, this endeavor promises to redefine the city’s waterfront while offering an immersive journey into the diverse aquatic ecosystems of the Pacific Northwest.

Laser scanning helped accurately measure the acrylic panels that created its underwater dome and the other innovative viewing places.

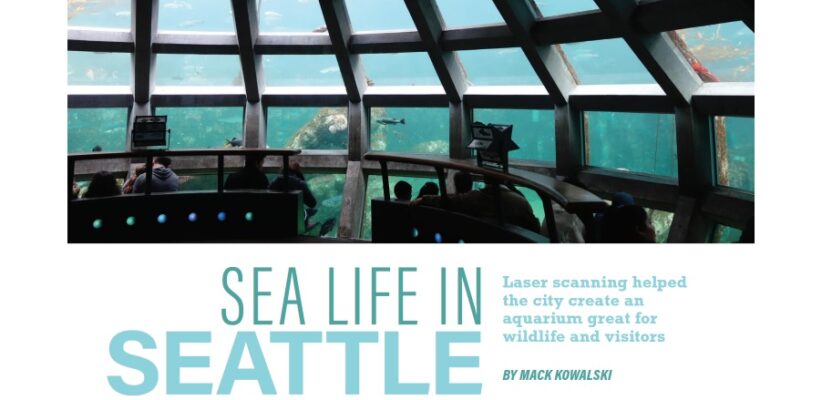

Central to the allure of the new Seattle Aquarium is its innovative design, which challenges the limits of aquatic architecture. Notably, the use of custom engineered acrylic viewing windows in constructing the main aquatic exhibits stands out. Turner Construction’s engineering partners’ expertise shines as they address the complexities of crafting these exhibits providing unrivaled views of marine life while ensuring structural integrity and safety.

Acrylic panels, prized for their clarity and strength, posed unique challenges in underwater exhibits. Reynolds Polymer Technologies engineered and manufactured the acrylic panels for Turner considering the water depth and shapes to fit the windows into LMN and MKA’s design. Through precise engineering, visitors can marvel at underwater wonders with peace of mind.

Immersive Underwater Experience

Thanks to Turner Construction’s mastery, visitors are transported into a mesmerizing underwater realm upon entering the Seattle Aquarium. Large acrylic panels offer unobstructed views of marine life. From sharks to colorful tropical fish, each moment is a captivating encounter.

Seattle Aquarium’s commitment to immersive experiences extends beyond visuals. Curated lighting, soundscapes, and interactive elements enhance the journey, educating and inspiring visitors as they explore simulated ecosystems and observe marine life.

Innovative Construction Techniques: Laser scanning

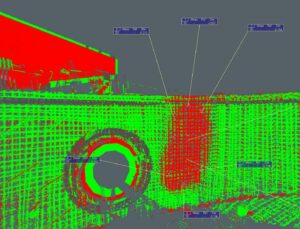

While the finished product captivates, the construction process relied on innovative technology for precision and efficiency. Laser scanning, which captures detailed 3D point clouds of physical spaces, proved invaluable. It ensured the accurate placement of structural steel, preventing costly errors.

While the finished product captivates, the construction process relied on innovative technology for precision and efficiency. Laser scanning, which captures detailed 3D point clouds of physical spaces, proved invaluable. It ensured the accurate placement of structural steel, preventing costly errors.

Moreover, laser scanning facilitated the seamless integration of the acrylic panels. Scans identified discrepancies in the concrete structure, ensuring a perfect fit for the custom-made acrylic pieces. This meticulous approach minimized delays and environmental impact.

Turner Construction utilized the RTC360 scanner and Cyclone 3DR software by Leica Geosystems, to compare 3D models to scans of the actual placement. This allowed for the swift identification and correction of any deviations, preventing the issue of any encroaching “burning” rebar, where steel protrudes beyond the concrete surface.

Laser scanning’s usefulness extended well beyond the initial construction phase. The acrylic panels’ high cost and delicate nature demanded a perfect fit within the concrete rebates. Here again, Turner Construction leveraged 3D scanning technology. Scans of the rebates were taken, and 3D models of the acrylic pieces were virtually placed within them. Utilizing best-fit techniques and analysis tools, any discrepancies in the concrete structure were identified and rectified before the expensive acrylic pieces even arrived on site.

Advancing Aquatic Education Sustainably

The Seattle Aquarium project exemplifies human ingenuity and environmental responsibility. Sustainable construction practices were prioritized, minimizing environmental impact. Laser scanning technology further showcased efficiency and precision, reducing waste, and ensuring project success.

The Seattle Aquarium project exemplifies human ingenuity and environmental responsibility. Sustainable construction practices were prioritized, minimizing environmental impact. Laser scanning technology further showcased efficiency and precision, reducing waste, and ensuring project success.

Beyond its architectural marvel, the Seattle Aquarium serves as a platform for education and conservation. Turner Construction’s innovative approach paves the way for a future where technology and environmental responsibility intersect to inspire generations.

Mack Kowalski has more than 10 years of experience in layout management and laser scanning to provide innovative solutions and services to our clients and partners. His passion to push the boundaries of technology and delivering high-quality results in every project led him to co-found LiDAholics consulting firm.